Description

Standard V Series Acrylic Food Production Line Mirrors

The impact resistant acrylic face of this food production line mirror makes it ideal for monitoring processes, reducing production costs, bottlenecks and workplace accidents. This product combines the strength and clarity of acrylic, with the durability of stainless steel fixtures. It offers an advanced plastics solution to your surveillance needs.

Features

- Premium quality acrylic mirror face

- ASA Vinyl back

- Stainless steel bracket and fixings (also available in galvanised steel option)

- Orange vinyl extrusion for visibility in the factory setting

- Unique J-Bracket for easy installation and adjustment

Suitable Uses

- Hygiene and safety environments

- Monitoring processes and machinery

- Regular cleaning regimes

- Prevent production line blockages and jams

Download Information Sheet pdf.

Download Information Sheet pdf.

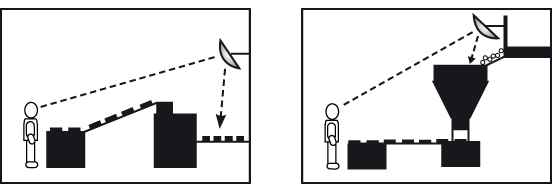

Positioning

Specifications

| Product Code | Size Diameter | View Distance | Mirror Face | Mirror Back | Bracket Length |

|---|---|---|---|---|---|

| 18220V | 300mm | Up to 21m | 2mm Acrylic | ASA Vinyl | 250mm J-Bracket |

| 18244V | 450mm | Up to 28m | 2mm Acrylic | ASA Vinyl | 250mm J-Bracket |

| 18266V | 600mm | Up to 38m | 2mm Acrylic | ASA Vinyl | 335mm J-Bracket |

| 18287V | 800mm | Up to 50m | 3mm Acrylic | ASA Vinyl | 335mm J-Bracket |

| 18295V | 1000mm | Over 50m | 3mm Acrylic | ASA Vinyl | 335mm J-Bracket |

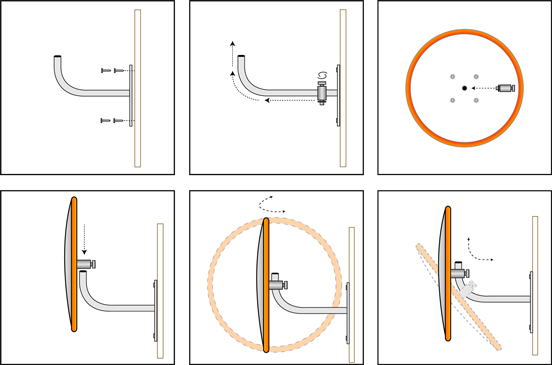

Installation Guide

Food and Production Line Mirror Installation Guide:

-

Decide the appropriate place to site the mirror to give maximum vision.

-

Fix J-Bracket to wall or ceiling using suitable fixing hardware (ie: screws, bolts). Allowing enough room to get the mirror on to the J-Bracket.

-

Thread adaptor into the back of the mirror.

-

Peel protective film off around the immediate edge of the mirror.

-

Slide the adaptor and mirror over the J-Bracket and adjust mirror to the desired position.

-

Tighten the locking bolt on the adaptor securely.

Cleaning Guide

Acrylic Mirror Cleaning Guide:

General Cleaning:

DuraVision™ recommend cleaning their acrylic mirror faces with soap and water and then with a clean, soft, lint free, damp cloth. Use a non-abrasive polish, such as Johnson’s Pledge or Mr Sheen for a clear bright reflection.

Saturate a clean soft cloth with polish, then spray the mirror face with polish. Wipe the wetted cloth over the mirror surface. With a another clean dry cloth buff the mirror face until it is clear of polish.

DO NOT USE:

- abrasives

- acids

- solvents such as petrol and laquer thinners

Graffiti Removal:

Any graffiti should be removed from the mirror face as soon as possible and preferably within 24 hours. To remove graffiti, use a non-abrasive substance such as De-Solv-it Stain Remover. Not all graffiti cleaning agents are suitable. Failure to use an approved cleaning agent may damage the mirror surface.

Scratches:

To remove scratches or repair blemishes on acrylic mirror faces only, use the following products:

- For cleaning use NOVUS plastic polish #1

- For fine scratches use NOVUS plastic polish #2

- For badly scratched surfaces use NOVIS plastic polish #3 followed by #2 and #1.